Analysis and control

A&B Laboratorios de Biotecnología has considerable experience and knowledge in microbiology, which allows guaranteeing the quality of its processes and products, reducing costs of “no quality” and improving and securing the image of the facility.

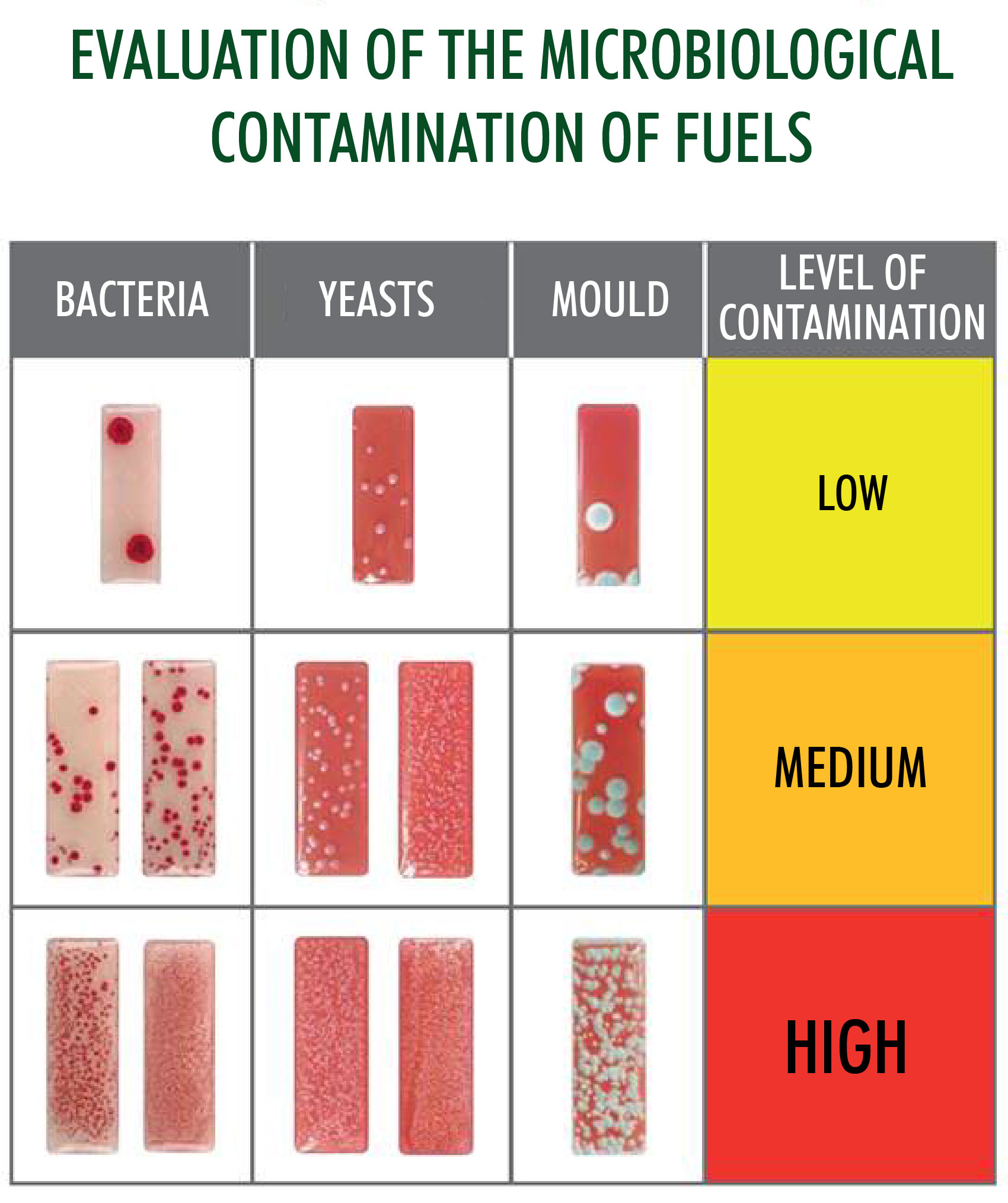

We provide you with a microbiological fuel analysis service that, complemented with our technical advice, will help prevent problems with quality alterations of your fuel.

Fuel Saver Protect – MT 171

One of the main problems of the fuel industries is the contamination of fuels in their storage, since that contamination can result in a loss of quality of the product in addition to operational problems derived from the fuel channelling and tank deterioration.

In recent years, microbial contamination is attracting great attention due to its impacts having substantially increased, probably because of the demand of diesel and fuels of a higher quality. The process of fuel production affects the final composition of the product, which determines the susceptibility of the product to be attacked by microorganisms.

Various factors will intervene in the development of microorganisms in a fuel, including the most important, the presence of water. Water, which is usually present, can have different origins, amongst them the condensed water on the walls of the tank and atmospheric humidity.

The use of organic and biodegradable biofuels (biodiesel), complying with the European legislation, makes the fuel itself serve as food for the microorganism. On top of that, these organic fractions favour water retention.

Elimination of sulphur in fuels to reduce contamination makes fuels be “unprotected” due to the sulphur’s biocide action.

Microorganisms can reach the tanks through the air and, once in the tank, some stick on the walls and others tend to locate in the interface water/fuel. In the study of fuel-contaminant microbial population, aerobic and anaerobic microorganisms were isolated.

The presence of microorganisms in tanks leads to an increase of water content due to the hydrocarbon microbial degradation. Additionally, the metabolic activity leads to peroxide and acid formation, increase of viscosity and sludge and corrosive residue formation. This all entail filtration problems, deterioration of tanks and fuel quality loss.

Storage tanks affected with microbial contamination may present the following:

- Supernatant solids in the water/fuel interphase of a sample from the base of the tank are signs of a microorganism growth process.

- Corrosion of the metal parts of the filter and appearance of a gelatinous mass on the surface of the filler is equally indicative of presence of bacteria and fungi.

- Settled solids on the base of the tank (anaerobic bacteria).

- Biofilm on the surface of the fuel and on the tank surfaces (walls and base).

For all this, it is recommendable to introduce a microbiological control additive, implement a protocol of good practises and follow-up of the tank condition and take measures to adequate the facility to the detected problem.

Our Fuel Saver Protect – MT 171 includes active ingredients that inhibit bacteria and fungi growth in fuels without altering the quality of the latter.