PREVENTION OF CONTAMINATION BY OILS AND HYDROCARBONS

Petrol stations, service stations and other distribution areas are industrial establishments, whose activity is linked to hydrocarbon presence. In those establishments spills of hydrocarbons on the pavement occur and they are diverted to a water treatment system consisting of a decanter and a hydrocarbon separator. These water treatment systems retain the fuel or the water that contains fuel, preventing a discharge to the sewage system and, therefore, reducing its impact on the municipal water treatment plant.

Equally, car wash facilities and mechanical workshops have these systems too. Fuel discharges and the water that sweep along those fuels in cleaning operations of car washes enter the water treatment system through the decanter, where sedimentation of the solid particles take place, mostly sand and dust particles. The next compartment is the hydrocarbon separator, in which hydrocarbons float on the surface.

This element is the one responsible for preventing the discharge of hydrocarbons.

This type of systems requires maintenance with the aim of assuring a good performance, therefore, preventing fuel contamination of water.

HYDROCARBON SEPARATOR MAINTENANCE

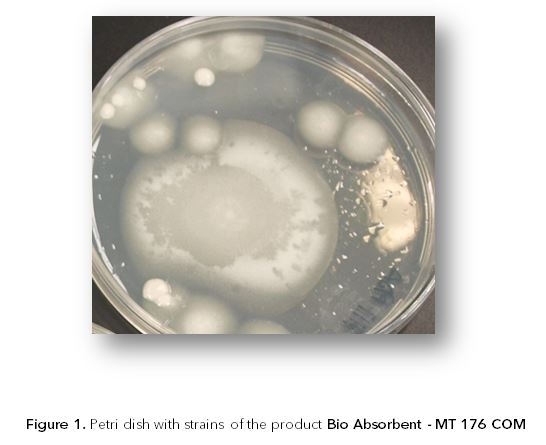

Bio Absorbent – MT 176-COM, optimises the performance of the hydrocarbon separators thanks to their double absorbing and biological degrading actions.

Bio Absorbent – MT 176-COM, contains a mixture of microorganisms specialised in hydrocarbon degradation. This allows a better performance of the absorbing component prolonging its activity.

The bacteria that the Bio Absorbent – MT 176-COM contains use the absorbed hydrocarbons as source of food. The final result is an increase of the bacterial population and a reduction of hydrocarbon content, since the biological activity of the bacteria transforms hydrocarbons into CO2 and water.